SUPPLY PIPING

Prior to the 1940s the majority of residential supply piping was galvanized steel. This is a very durable pipe that can last for generations. In the late 1930s, and especially post-World War II, copper supply piping became the industry standard. In the 1970s there was increased use of various types of plastic piping. However, copper piping has continued to be the material of choice for most traditional plumbing contractors to this day.

I

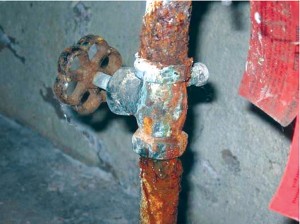

Although galvanized pipe is very durable, it eventually begins to rust, and ultimately leak. The other downfall to galvanized pipe is the eventual build-up of sediment or corrosion inside the pipe. This results in a “hardening of the arteries” affect, eventually adversely affecting water flow and water pressure. For this reason replacement of galvanized piping with copper usually results in an increase in pressure.

Rusty and leaking galvanized pipe

Partially plugged old galvanized pipe

Copper pipe with soldered fittings does not rust or deteriorate in the same manner as galvanized pipe. Also, it is not prone to restricted flow from eventual build-up in the pipe. These qualities have made copper supply piping desirable for generations.

I

Plastic supply piping has become popular greatly because the cost of copper pipe has increased. The most common type of plastic pipe in earlier years was CPVC (chlorinated poly vinyl chloride). The joints of this piping are glued together. It provides for a less costly alternative to copper, but it is less durable or reliable.

I

The most modern type of “plastic” pipe is PEX (cross-linked polyethelyne). This is the color coded blue and red pipe that has prompted many of your inquiries as of late. The early returns on this type of piping have been very positive. Plumbing contractors in general have praised the cost benefits, ease of use and dependability of this pipe.

PEX supply piping with clamped fittings

PEX piping connected to copper

I

PEX piping can be used in two ways. Sections of the pipe can be joined or connected in a similar design to that of galvanized or copper pipes with elbows, “T”s, etc. The joints are rigidly clamped together (galvanized pipes have threaded fittings while copper pipes have soldered fittings).

I

PEX piping can also be used in a “manifold” design. The manifold is located in the basement, near the main water service. This manifold feeds individual hot and cold pipes that seperately run from the manifold to each fixture in the house. This type of system greatly minimizes the number of joints or connections in the plumbing system. There is a single pipe feeding each fixture directly from the manifold to the individual fixture. Since plumbing problems often times occur at the joints or connections, a manifold system can theoretically reduce the number of problems that might be experienced as time passes. Also, the joints of PEX piping restrict flow and reduce the pressure. Manifold systems result in more uniform pressures to the various plumbing fixtures in the house. Although manifold systems are not the norm, we have inspected a number of modern homes with this type of system.

WASTE PIPES

Similar to supply piping, waste piping has also evolved over the years. Steel or cast pipes were used for decades in the early to mid-1900s. Much like its supply counterpart this type of piping was durable and reliable, but was also prone to eventual rusting and leaking. These pipes can become restricted or plugged.

Inside of old galvanized drain

I

Cast iron waste piping was primarily used on the larger piping (3” and greater) and is less prone to corrosion, as compared to galvanized piping. This waste piping is still used commercially; especially underground.

I

Copper waste pipe was used in the late 1950s to the early 1960s. This piping is very dependable, but it is cost prohibitive and somewhat labor-intensive when soldering large joints.

I

In the early 1970s “plastic” or PVC drain pipe became the norm for residential use. This remains the case to this day. PVC drains are durable, reliable and do not tend to be prone to unusual restrictions or blockages. Most PVC drain piping is glued at its fittings. These connections are very dependable and are not prone to leakage. Threaded couplers are also used on plastic or PVC drain pipes for traps and drain connections. As a result, traps and drain extensions are very easy to clean and replace on an as needed basis.

PVC Drain connected to older cast drain cleanout at floor level

I

We hope that you find this information to be beneficial, and that it helps answer some of the questions that you may have on this topic. As is always the case, please do not hesitate to contact our office if we can be of any assistance.